WE OFFER TURNKEY SOLUTIONS TO AUTOMATE PASSENGER VEHICLE DRIVING

IN FACTORY GROUNDS, VEHICLE LOGISTIC YARDS & PROVING GROUNDS.

Embotech’s technology platform is powering the AVM solution and enables vehicles to maneuver safely, smoothly, and efficiently in real-time. Our AVM solution is infrastructure based in terms of sensing and compute, requires minimum intervention on the vehicle side and can coordinate multiple vehicles simultaneously.

World’s First AVM System in Production Facilities

COMPLIANT WITH ALL RELEVANT SAFETY STANDARDS

FOR AUTOMATED DRIVING WITHIN FACTORY GROUNDS AND VEHICLE LOGISTIC CENTERS – CERTIFIED BY TÜV SÜD.

Automated Vehicle Marshalling (AVM)

How?

Our AVM solution uses smart infrastructure to automate vehicle operation. This innovative approach minimizes the requirements on the vehicle itself, allowing us to control almost any standard production car.

Watch the video below for a deeper dive into how it works!

©BMW AG

Why it matters? The Impact of AVM

Current methods of manually driving vehicles through different stations of the production is costly and inefficient. AVM offers a range of advantages

Cost Reduction

Saves 1/2 of the driver’s costs & eliminates damages.

Replaces traditional conveyors.

Efficiency Improvement

Minimizes driver and vehicle travel times.

Eliminates human error, e.g. misplacement of vehicles.

Production Flexibility

Adapts to changing layouts, growing volumes and new use cases.

Time-to-market of new models/variants.

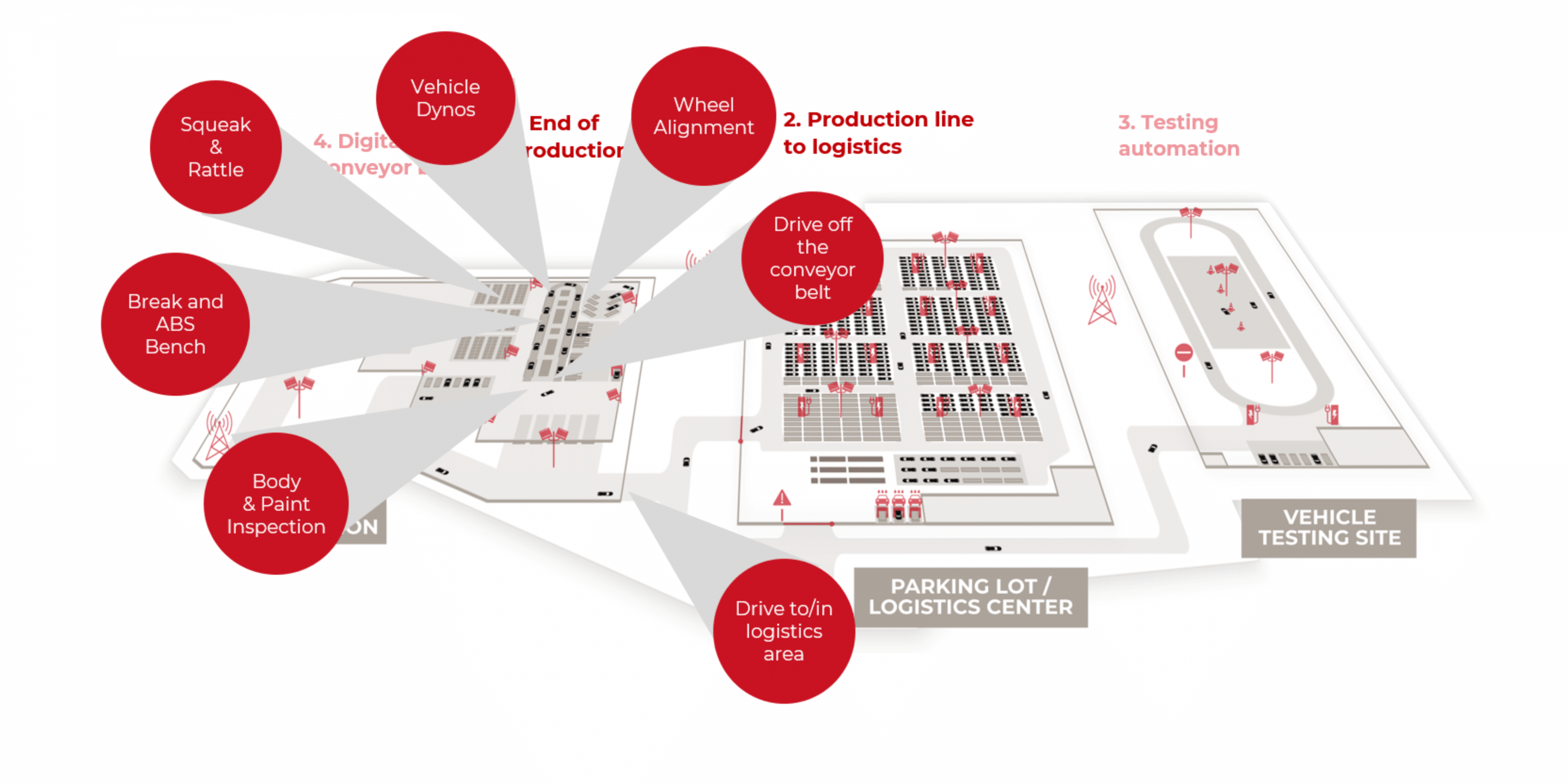

Use cases

Our solution covers all use cases to be found in automotive factories: Conveyor belt exit, Wheel Alignment, Body & Paint Inspection, Squeak and Rattle, Engine Test, Sensor Calibration, Drive to Logistics.

The AVM advantage: Why choose Embotech?

Our solution offers a wide range of advantages:

safety

Safety Certified System & CE Marked – designed for highest availability.

Live in a production environment with a German OEM since July 2022.

Capabilities

Fully flexible planning in real-time, can react on e.g. road or test rig closures.

Max speed 30 kph – co-existence with mixed traffic/human-driven vehicles.

Easily configurable for all vehicle models/sub-models.

Cost Efficiency

No special HW needed, all HW is off-the-shelf (OTS).

No changes required in the infrastructure apart from lidar placement.

Lidar placement supported by advanced tooling.

automated vehicle testing

How?

With Embotech’s proprietary technology, we use smart infrastructure to automate vehicle testing operations. Similar to AVM, the requirement on the vehicle are basic.

©BMW AG

Looking for more information?

If you’d like to find out more about our AVM Solutions, let us know. Either use the webform on the right or book a meeting via the link below. Our team of experts will be happy to discuss more details with you.