What is probot?

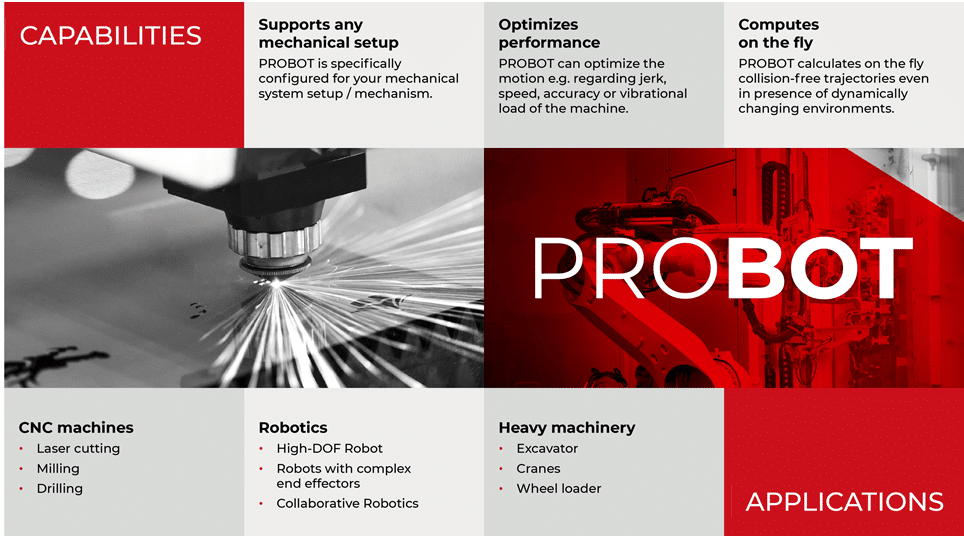

PROBOT is Embotech’s solution to the problem of motion planning for robotics, industrial machines, and heavy machinery. The motion planning is an essential task for autonomous operation of these machines, e.g. for use within smart factories.

PROBOT calculates a collision-free trajectory on the fly while considering the changing surrounding environment information. The technology is based on continuously predicting the movement and solving an optimization problem in real time.

Tailor-made motion planning

PROBOT is designed such that a tailored motion planning algorithm can be deployed for every robot and industrial machine. The big strength of PROBOT is the possibility to consider the specific needs of your application. This concerns the mechanical setup you are looking at. For instance, high-DOF robots and complex end effectors are handled.

The design philosophy enables the use within a wide range of applications, from CNC machines to excavators. At the same time, requirements on the motion trajectory can be specified: While CNC machines are typically optimized for reduced jerk, many applications in robotics are optimized for minimal travel time.

configure your individualized algorithm

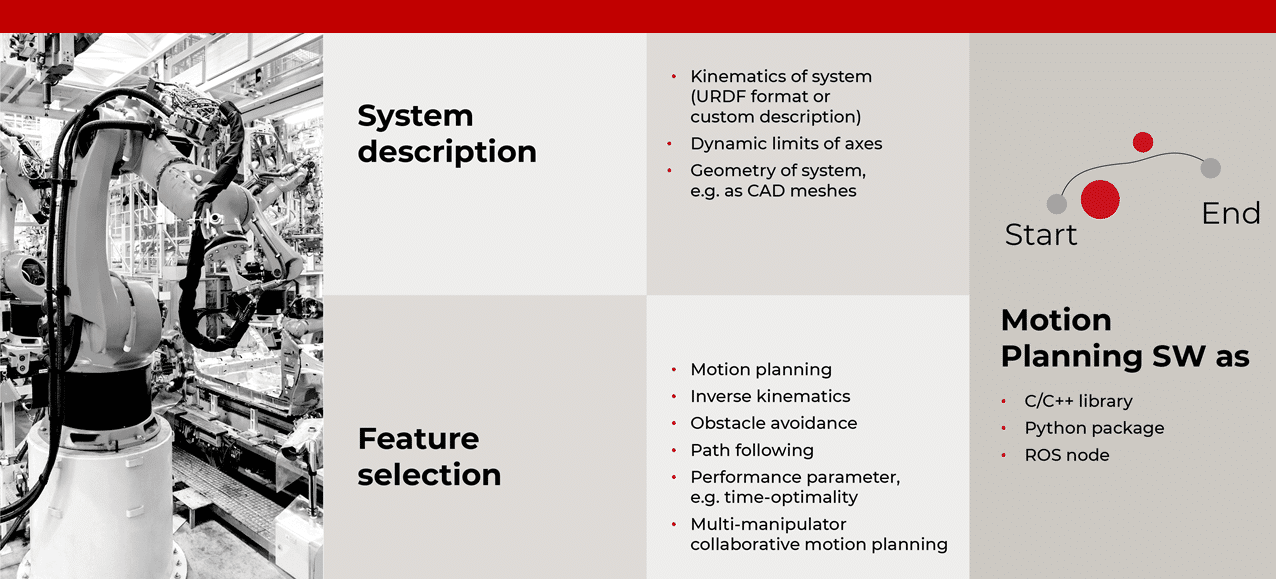

The motion planning algorithm can be individualized for your specific setup. There are several features that can be configured. The kinematics of your system is considered by a URDF format or by a custom description. Additionally, limits on axes can be included in the algorithm. This concerns the geometrical limits as well as limits on velocity and acceleration. To check for collisions, the geometry of the system to be controlled can be specified, e.g. as CAD meshes.

Not only is it possible to individualize the system setup but also the task description. Various features can be selected, such as motion planning, path following and inverse kinematics, all while avoiding obstacles. This includes even the task of holistic motion planning for a multi-manipulator setup, where a collaborative motion is needed. In addition, the performance parameter for the movement, such as time-optimality of jerk reduction can be specified.

Data Flow for integration in your application

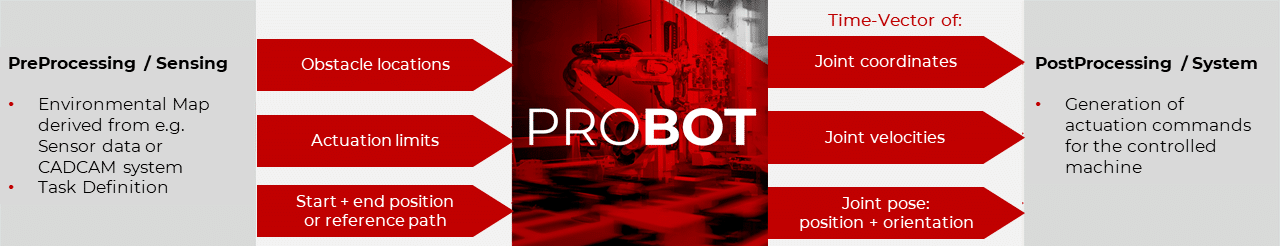

The major inputs to the PROBOT motion planner are the start and end position of the path as well as the obstacle locations. As a result, PROBOT calculates the optimal motion plan with outputs being the joint coordinates and velocities and likewise the joint pose, in terms of position and orientation. PROBOT can be integrated flawlessly in your software stack.

The inputs for PROBOT are calculated by a preprocessing / sensing layer. This layer considers the environmental map derived from the sensor data and the task description. The outputs of PROBOT are postprocessed before applying it to the physical actuators. For instance, they are sent to the low-level CNC controller or the robot controller.

Integration in TwinCAT 3

PROBOT is compatible with Beckhoff’s TwinCAT 3 environment. It is delivered as a TcCOM module upon request, allowing TwinCAT 3 users to easily add our best-in-class numerical optimization software to their production systems. No specialized algorithmic or software knowledge is required. PROBOT addresses common challenges in industrial automation like trajectory planning and control, process control, energy usage optimization, and task scheduling.

Our numerical optimization engine then solves these problems in real-time. This enables manufacturers to reliably operate their equipment at peak performance levels even under tight computational limits. The effectiveness of PROBOT’s integration in TwinCAT 3 is demonstrated by its advanced position control application for CNC machines.

Looking for more information?

If you’d like to find out more about PROBOT, let us know. Either use the webform on the right or book a meeting via the link below. Our team of experts will be happy to discuss more details with you.